Chroma's 17020 is a high precision system specifically designed for secondary battery modules and pack tests. Accurate sources and measurements ensure the test quality that is suitable to perform repetitive and reliable tests that are crucial for battery modules / packs, for both incoming or outgoing inspections as well as capacity, performance, production and qualification testing.

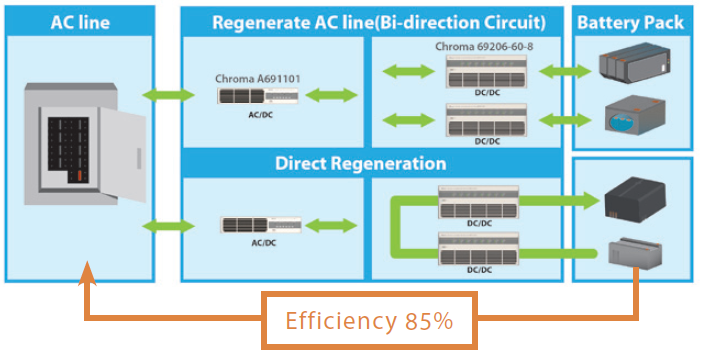

Chroma's 17020 system architecture offers regenerative discharge designed to recycle the electric energy sourced by the battery module either back to the channel s in the system performing a charging function or to the utility mains in the most energy efficient manner. This feature saves electricity, reduces the facilities thermal foot print and provides a green solution by reducing the environmental impact on our planet.

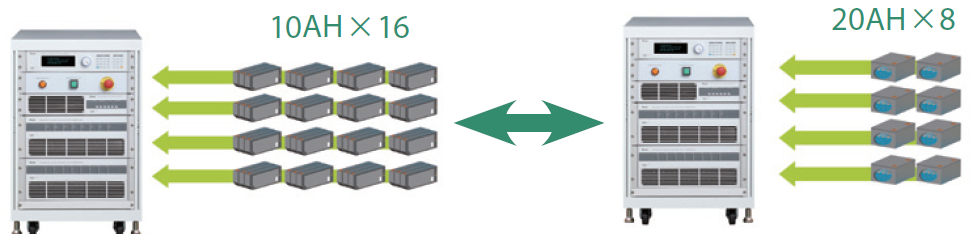

Chroma's 17020 system is equipped with multiple independent channels to support dedicated charge / discharge tests, on multiple battery modules / packs, each with discrete test characteristics. The channels can easily be paralleled to support higher current requirements. This feature provides the ultimate flexibility between high channel count and high current testing.

Advanced hardware design can create seamless transitions between maximum charge and maximum discharge (or maximum discharge and maximum charge) with a rapid 50 ms conversion. This feature allows for charge/discharge modes simulating real world scenarios.

Chroma's 17020 system has flexible programming functions and may be operated with Chroma's powerful Battery Pro software. Battery Pro utilizes the system to create cycling tests from basic charge or discharge to complex drive cycle testing for each channel or channel groups. A thermal chamber control can be integrated into a profile and triggered by time or test results yielding a dynamic profile. Battery Pro's features allows quick and intuitive test development to eliminate the need of tedious scripting or programming by a software engineer.

There are multiple safety features including Battery Polarity Check, Over Voltage Protection, Over Current Protection check and Over Temperature Protection to ensure protected charge / discharge testing. In the unlikely event of power or computer communication loss, the data is securely stored in the system, on a non-volatile memory, protecting against potential data loss and allowing for continuous flow after restart.

Test Items

- Drive cycle simulator

- Learning test for manufactory

- Life cycle test

- Balance control test

- DCIR test

- Capacity test

- Performance test

- Reliability test

- Over charge/dischargetest

- Thermal test

Regenerative Energy

- Regenerative battery energy discharge

- Direct recycle back to the battery unber charging

- Regenerate to grid

- Low heat output

- Reduce air-conditioner power consumption

- The THD of 17020 system is under 5% at rated power

- The PF is over 0.9 at rated power

- Return to factory directly

Parallel Control - Up to 60 Channels

Parallel Function

Supports Various Capacity Batteries in Parallel

|

Battery companies have various capacity configurations. Some customers may purchase a high power system to test all capacity battery packs. The downside is that the measurement accuracy is not sufficient for small-capacity battery packs. Using Chroma's system, customers can test under individual or parallel channels for higher capacity battery packs. The system supports di�erent capacity batteries from a base system configuration. |

Driving Cycle Simulation

|

The battery pack always is used at quick and un-regular current condition. The system simulates the real condition on battery pack by working condition simulator.

- Import dynamic charge/discharge power or current waveforms to simulate the DRIVE CYCLE or the actual application.

- Support Excel (xls) format

- There are 720,000 points of driving profile memory to save the waveform profile in each channel.

- Minimum Δt:10ms

High Accuracy Capacity Calculation

Voltage/current sampling rate of 50kHz used for calculating capacity ratings in dynamic waveform mode

- V/I sampling rate : 50KHz (per 20μs)

- Integrate calculus:

- I for capacity

- VxI for energy

|

System Functions

Independent Channels

- Independent channel operation

- Independent testing data

- Independent protection

- Independent testing process

Operating mode

- Constant current (CC) mode

- Constant voltage (CV) mode

- Constant power (CP) mode

- Constant voltage-limit current mode (CC-CV)

- Waveform current mode

- DCIR mode

- Rest

Cut-off mode

- Time (s)

- Capacity (Ah)

- Voltage (V)

- Current (A)

- Temperature (℃)

- Channel data in data logger (Option)

Protections

- Over voltage protection (V)

- Under voltage protection (V)

- Over current protection (A)

- Over temperature protection (℃)

- Over capacity protection (Ah)

- Wire loss protection (ΔV)

- Channel data in data logger (Option)

- -ΔV /+ΔV protection (V)

- +ΔI /-ΔI protection (A)

- Delta Protection: Protect internal short of battery cell

Testing Data

- Independent testing data

- Detail report: STEP/TEST TIME/TEST TIME ID/

Cycle/Loop/STEP MODE /STEP TIME/

VOLTAGE(V)/CURRENT(A)/CAPACITY (Ah)/

Energy (Wh)/ TEMPERATURE (℃)/

Data Logger Channel (Option)

- STEP/STEP NO/LOOP/CYCLE/STATUS/

STEP START TIME/ STEP MODE /CUT OFF VOLTAGE(V) /

CUT OFF CURRENT(A)/CUT OFF CAPACITY(Ah) /

DCIR(mOhm)/Energy (Wh)/TEMPERATURE (℃)/

Data Logger Channel (Option)

|

Compact Size

- The dimensions of a regenerative system is smaller compared to a system that has to dissipate energy.

Continuous transition

Continuous charge and discharge transition: No time delay to transit from charge to discharge. The user can verify the battery pack for a design limit. Continuous CC-CV transition: No overshoot current or voltage to damage the battery when transiting CC-CV.

Response time

- The trip time between maximum charge and maximum discharge current is 50ms.

- Smooth current without overshoot for avoiding to damage the battery.

Temperature Measurement

- Temperature measured for each channel within the range of 0~90℃±2℃

- 4 sets of measurements (max.) per channel to measure the battery surface temperature

▲ Thermal sensor

Test for battery pack with split connections

For some battery pack designs, the charge and discharge ports are split into two connectors. The user can set the 17020 software to select charge/discharge using either a single connector or two connectors separately.

Data Recovery

- 60 min of temporary data storage when sampling time is 1 sec.

- Save the test settings to resume after power failure is recovered

|

Software Function

The 17020 Test system is specifically designed to meet the various requirements for testing secondary battery packs with high safety and stability. Charge and discharge protection aborts tests when abnormal conditions are detected. Data loss, storage and recovery are protected against power failure.

User friendly

- Real-time multi channel battery pack status browse

- Icon Manager: Test status of each channel is managed through different icons, easy to read and understand.

- Authority management: It sets the user's authority for operation.

- Fault record tracking: It records the abnormal state of each channel independently.

Recipe editor

- 255 charge/discharge conditions

- Sets dual layer loops (cycle & loop) with 9999 loops per layer

- Able to edit dynamic charge/discharge waveform with 10ms current switching speed

- Testing Step: CV/CC/CP/CC-CV/Waveform current/DCIR)

- Cut-off conditions

(time, current, capacity, cut-off voltage, cut-off current, etc.)

- Next Step: Next/End/Jump/Rest

Testing Data

- Generate the detailed report and step report

- Customized report format

- Exports test reports in PDF, CSV and XLS

- Graphical report function

- Report analysis Function: Users can create customized reports such as life-cycle report, Q (AH)-V(V) report, V(V)/I(A)/T( ℃)-time report⋯etc through the user-defined X and Y axis parameters.

- Real-time browsing test reports of each channel

- Diversified reports & charts: Real-time report, Cut-off report, X-Y scatter chart report

Software integration

- Thermal chamber: Synchronize temperature control with charge/discharge profile

- Data logger: Temperature or voltage data record that can be used for setting Cut-off and protection conditions

- BMS data record: Software setting to read data from BMS by data communication unit A692000/A692001. This supports SmBus and CAN bus. The data can be set in the conditions for cut-off or protection during testing

|

CHROMA Data logger 51101 provides synchronized sampling with constant data acquisition rate.

- Minimun: 200 ms

- Interface: Ethernet

|

System Configuration