Chroma 62000D Series programmable bidirectional DC power supplies have both power source and load characteristics. Capable of feeding power from the device under test (DUT) back to the utility grid, these two-quadrant power supplies are ideal for testing energy storage systems in renewable energy applications such as solar PV/storage hybrid inverters, battery power conditioning systems (PCS), and simulating charging and discharging of energy storage batteries. 62000D also has applications in testing power components in electric vehicles (EVs) as well as bidirectional on-board chargers (BOBC), DC-DC converters, and DC-AC motor drivers, enabling bi-directional power conversion simulation tests without the need for actual batteries.

Traditional DC power supplies need protection diodes to prevent back EMF from damaging the power supply during motor testing. However, 62000D bidirectional DC power supplies can drive the motor and also efficiently regenerate EMF to the grid, avoiding the need for blocking diodes while saving space, energy, and configuration effort. In addition, the fast transient response of the 62000D enables seamless quadrant changing in less than 1.5ms (-90% to +90% load).

The 62000D series is available in 3U and 4U form factors, all boasting high power density. The 3U models come in single-unit output power ratings of 6kW/12kW/18kW, while the 4U models have single-unit output power rated 36kW/45kW. The 62000D-HL model features unique dual-range output capability, allowing a single unit to provide both High (2000V/60A/45kW) and Low (650V/180A/45kW) output ranges. This enables the unit to meet high-current, fullpower test conditions of the DUT while also meeting high-voltage, full-power test requirements, suitable for wide-ranging testing needs such as the 400V and 800V battery platforms used by EVs and EV supply equipment (EVSE).

The 62000D series supports up to 100 programmable sequences through its List Mode feature. Its fast transient response time meets many testing needs, including those defined in the LV123 and LV148 standards for EV components. When used with Chroma’s Softpanel software, users can conveniently conduct complex tests with a simple press of a button.

The 3U models have a universal 200-480Vac input voltage and the 4U models have a universal 380-480Vac input voltage. All units have active PFC low current harmonic feedback, which significantly reduces electricity costs and power system configuration in high power test environments, lowers test environment temperature, and is suitable for power systems in all regions globally. Various control methods are available, supporting digital USB/LAN/CAN/GPIB interfaces and analog APG interface control, with the 2000V models additionally supporting CAN FD.

Power Conversion Testing of Electric Vehicles and Microgrid Storage

Renewable energy sources such as PV, EV, fuel cell, and battery are the market trend as the replacement of traditional energy sources (coal, oil, etc.). Yet, the subsequent rising need for electricity will actuate the faster commercialization of distributed energy storage in microgrids. The bidirectional design of power conversion devices urges battery applications to achieve high efficiency, high voltage conversion, and high power density direction, which prompts the need for battery simulation (bidirectional power supply) testing designs.

|

With the widespread use of EVs, there is also a corresponding demand for sound residential, commercial, and city charging networks. This has resulted in a smart grid and energy storage system ecology—from 5kW-30kW smart home charging/storage systems, to 30kW-500kW integrated commercial PV/storage/charging stations, to dispersed large-scale MW-level storage combined with renewable energy sources like solar, wind, and fuel cells. With voltage systems for these high power applications also developing toward 1500V-2000V, battery simulation equipment for related power conversion devices also needs to meet these voltage and power requirements.

As for the test equipment needs of high power conversion devices like PCS, ESS, chargers, and inverters, users often need to consider factors like size, weight, equipment utilization rate, flexible disassembly/re-assembly into multiple power systems for flexible scheduling, and system fault maintenance time affecting R&D and production. The 62000D-HL bidirectional DC power supply features master/slave parallel control capabilities. Single-unit parallel operation is simple and fast. Integrated into a cabinet, these power supplies are suitable for testing string-type PV inverters, able to separately supply multiple MPPT inputs, or quickly parallel to high power input—convenient for use in R&D labs, validation units, and production lines.

|

▲62450D-2000HL

Master/Slave Parallel in a Single Cabinet up to 360kW

*Please call for more information

|

Next-generation 62000D-HL Model Features High Power Density 45kw@4uh and Dual Output Ranges in One-click Switching

With the maturation of SiC semiconductor devices and the gradual increase in charging standard voltages, EVs are developing toward improved charging efficiency and range by evolving their battery platforms from 400V to 800V. This in turn is driving up the voltages for onboard electrical control systems like BOBC, DC-DC, motor control units (MCUs), and inverters.

Taking a 22kW bidirectional on-board charger (BOBC) compatible with both 400V and 800V as an example, the typical voltage range would be 200V-900V or even higher. The design of the test equipment must account for rated test conditions as well as over-voltage (>130%) protection test margins. Generally, the maximum charging current falls within the 200V-450V range, so current also needs to consider ripple peaks and over-current (>120%-150%) protection test ranges. Under such an operating range, users may need one high-voltage bidirectional DC power supply over 1200V, as well as another with at least 120A current capability. The Chroma 62000D-HL model satisfies this ultra-wide operating range requirement with a single device.

The 62000D-HL bidirectional DC power supply features two ultra-wide output ranges within a single unit. For the 62450D-2000HL model, the High range provides 2000V/60A/45kW, while the Low range offers 650V/180A/45kW. Users can easily switch between the needed ranges to meet test conditions requiring either high voltage or high current. With such a wide operating range, in addition to the High range satisfying high voltage test points, users can even utilize the Low range's high current capability in load mode to perform long-term reliability testing on two devices under test with a single piece of equipment.

Users can switch between the 62000D-HL model's dual output ranges by simply pressing the switch on the front panel touchscreen, or by sending a remote command. In an automated test equipment (ATE) production line system, only one 62450D-2000HL is needed - switching between the High/Low ranges via command satisfies both output range operations. After switching, the test instructions can proceed without interruption. Users do not need additional manual disassembly/re-assembly of bridging fixtures at the equipment output terminals, making for a seamless and safe testing experience.

Two-in-One: Bidirectional DC Power Supply and Load

The Chroma 62000D boasts a bidirectional switch-mode power supply design that offers two-quadrant operation with positive current/positive voltage as well as negative current/positive voltage, enabling both DC power supply output and regenerative DC load. The absorbed energy is fed back to the grid with up to 93% efficiency and can operate in constant voltage (CV), constant current (CC), and constant power (CP) mode. Compared to a traditional power supply and load, the 62000D two-in-one bidirectional DC power supply saves space, reduces energy loss and heat dissipation, and is easier to wire and configure.

Today's electric cars typically carry on-board chargers that manage power flow bidirectionally between the vehicle and the grid for operations such as V2G (Vehicle to Grid), V2L (Vehicle to Load), and V2H (Vehicle to Home). The 62000D also offers a pure electronic load mode with constant current (CC), constant power (CP), and constant resistance (CR) control, especially useful for simulating battery charging behavior during development and testing of BOBCs. In contrast to traditional methods requiring separate instruments for DC power supply and regenerative DC load, a single Chroma 62000D unit now suffices for conducting both charging and discharging tests autonomously.

▲Bidirectional on-board charger testing configuration

Fast Transient Response< 1.5ms

Chroma 62000D allows seamless current conversion between the two quadrants of supply and electrical load without compromising output characteristics or causing damage. In many bidirectional DC-DC and DC-AC battery charge/discharge tests demanding rapid transition between charging and discharging, the 62000D's high-speed transient response proves invaluable, boasting an output voltage response time of less than 1.5ms for a -90% to +90% load change.

To assess acceleration and braking of the motor driver under real-world driving conditions, the conversion between battery and power components will involve supply and recharge of electrical energy. The 62000D’s fast transient response across two quadrants adeptly simulates the battery according to the actual needs of the motor, offering stable voltage and enabling current recharge during braking.

▲Start-stop system motor driver test application

Testing Standards LV123/LV148

Driven by global energy efficiency and carbon reduction trends, the auto industry has established technical development standards that define tests for a variety of electric vehicles. The LV123 standard specifies the electrical characteristics and safety standards for high-voltage components, while the LV148 covers tests for electric and electronic components in 48V electrical system motor vehicles. Chroma 62000D has a high-speed CV dynamic response slope that can be controlled up to 200V/ms, applicable to the electrical characteristics tests of many vehicle standards. When used with the Chroma Softpanel, users can execute all these tests effortlessly at the push of a button.

Learn more on :Model 62000D Series Graphical User Interface - SoftPanel

Battery Simulation Function

The 62000D serves as a bidirectional DC power supply capable of being charged or discharged by an external power source. When used with software, 62000D units become battery simulators that can replicate operation at various capacities (SOC) or import specific battery characteristics V-I curves. This capability facilitates product evaluation under diverse battery capacities and characteristics. Suitable for testing an array of products like BOBC, PCS, ESS, or motor drivers, the 62000D series offers a versatile solution for battery simulation needs.

Learn more on :Model 62000D Series Graphical User Interface - SoftPanel

Solar Array Simulation Function (Optional)

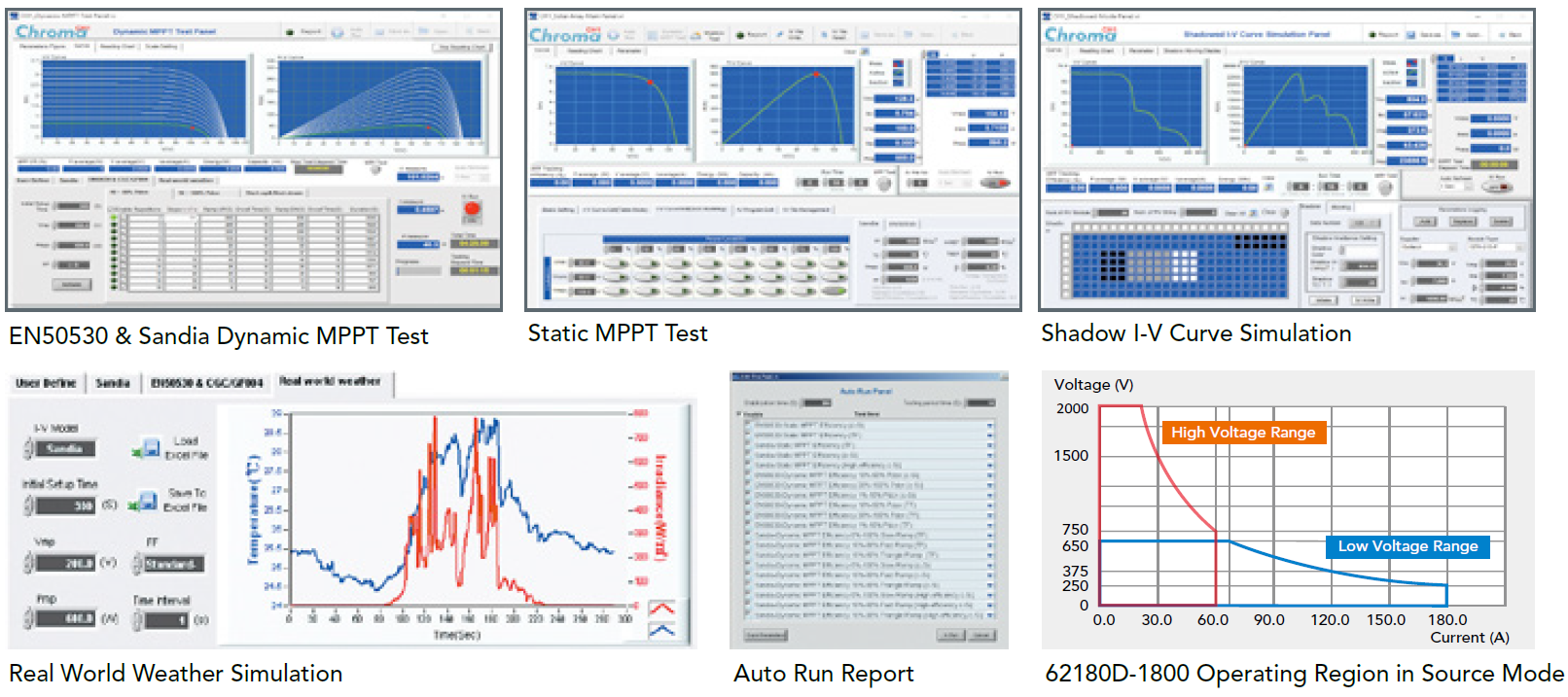

The 600V/1200V/1800V models have built-in EN50530 and Sandia SAS models that allow users to easily program different solar cell I-V characteristic outputs via the front panel or remote SCPI control. The SoftPanel software includes static & dynamic MPPT test, shadowed I-V curve simulation, real-world weather-based I-V curve variation testing, and automatic static & dynamic MPPT tests with report generation in Excel format, ideal for validating the performance of series-connected PV inverters. Additionally, the 62180D-1200 and 62180D-1800 models support master/slave parallel configuration of up to 30 units, with output specifications reaching 540kW/1200V/1200A & 540kW/1800V/1200A respectively. This enables adaptation for testing high-voltage 1100V and 1500V commercial (15k-100kW) string inverters and distributed energy resource (150k-500kW) inverters.

High Voltage PCS Testing

A power conditioning system (PCS) serves to facilitate bidirectional power conversion between battery systems and the grid, with the latest devices boasting terminal battery voltages of up to 1500V, featuring charge/discharge functionality, active power control, reactive power regulation, and off-grid switching. A common issue for users is how to prepare an actual high-voltage battery for testing the charge/discharge transition performance of PCS units, typically with a standard transition time of <100ms. Achieving this level of performance while ensuring R&D verification, manufacturing reproducibility, controllability, and safety can be daunting. With the high-voltage 62180D-1800 model, users can parallel up to 30 units to achieve an output of 540kW/1800V/1200A. This setup effectively replaces real battery simulation as either a power supply or regenerative load, allowing for continuous transient response testing with an uninterrupted flow of current.

Safety and AC Fault Protection

Chroma 62000D bidirectional DC power supplies have energy recycling functionality that returns energy to the grid. The internal protection design serves to identify input voltage and frequency anomalies. When detecting any anomalies, the 62000D will automatically turn off the output to ensure safe use of the grid. The 62000D is set up with OVP, OCP, OPP, OTP, Fan Fail, and AC Fault protection circuits. AC Fault protection includes OVP, UVP, Unbalance, Freq. Error, and OCP.

Advanced Ultra-Wide Output Range

For testing of 11kW BOBC, taking into consideration maximum current ripple, inrush currents generated during vehicle DC-DC startup, etc., the test equipment must be able to provide approximately 20%-50% current margin beyond the steady-state charging current specifications. Therefore, for models 62120D-1200 and 62180D-1200, Chroma has further enhanced the current capability under ambient temperature conditions and for specific versions, achieving an output range of 1200V/55A/13kW-19.5kW.

For string PV inverter test applications, to cover residential to commercial power needs including 1.5x overdimensioning, the maximum short-circuit current per MPPT channel has been gradually increasing. Facing this equipment demand, the current provided per MPPT channel also gets a boost. For the 62180D-1800 model, the voltage meets the needs of 1100V and 1500V systems, while the current has been enhanced to 55A. Under ambient temperature conditions and for specific versions, the output range reaches 1800V/55A/19.5kW. Please refer to the specification sheets for related conditions.

High Power System Integration

|

Chroma offers high-power bidirectional power supply integration services ranging from 54kW to 540kW/1800V/1200A systems. These power systems come with multiple protections, including AC circuit breaker with overcurrent protection, leakage current detection, emergency stop button device, input voltage phase deficiency, over-voltage, under-voltage, system over-temperature, and fan failure protection. They are suitable for both R&D purposes and long-term testing on production lines.

* * Model 62180D-1200 & 62180D-1800 can support 30 units in parallel, up to 540kW.

* For parallel requirements of models 62360D-2000HL & 62450D-2000HL, please contact your local Chroma office.

|

Universal AC Power Range 200~480vac

Chroma 62000D bidirectional DC power supplies are equipped with an active PFC >0.97 for low energy consumption and high conversion efficiency. Moreover, to fit the universal AC power input range, the 62000D series has a very wide input power range of three-phase 200- 220Vac and 380-480Vac. Users can purchase one single device without having to configure it for use in other areas.

* Models 62360D-2000HL and 62450D-2000HL have an input voltage range of 3-phase 380-480Vac.

Remote Control

Chroma 62000D supports various communication interfaces, allowing users to connect and control the unit via standard USB, LAN, and optional GPIB interfaces with a PC. It also features a CAN interface compliant with CAN 2.0 A&B specifications for both 11-bit and 29-bit formats, enabling high-speed reading of V/I/P parameters within 10ms.

User-Friendly Interface

Chroma 62000D sports a next-generation GUI with an intuitive, smartphone like touch panel. Using the icons on the touchscreen interface, the user can perform any voltage/current settings and measurements, program sequence control settings, preview output waveforms, and more.

Softpanel

The 62000D series can be operated from the front panel controls or from available softpanel. This user friendly software includes all functions of the 62000D series and is easy to understand and operate. The 62000D can be controlled via GPIB, USB and Ethernet interfaces for remote control and automated testing applications.